Precision Product Inspection

Process automation often creates concerns like “what if we start making bad product?” Our suite of inspection systems delivers confidence as standalone systems or integrated process’ to ensure critical parameters are maintained. Inspection tools are powered by 2D or 3D scanning tools.

-

Bin Picking

Bowl Feeding

Tray Systems -

Part marking that can incorporate serialization

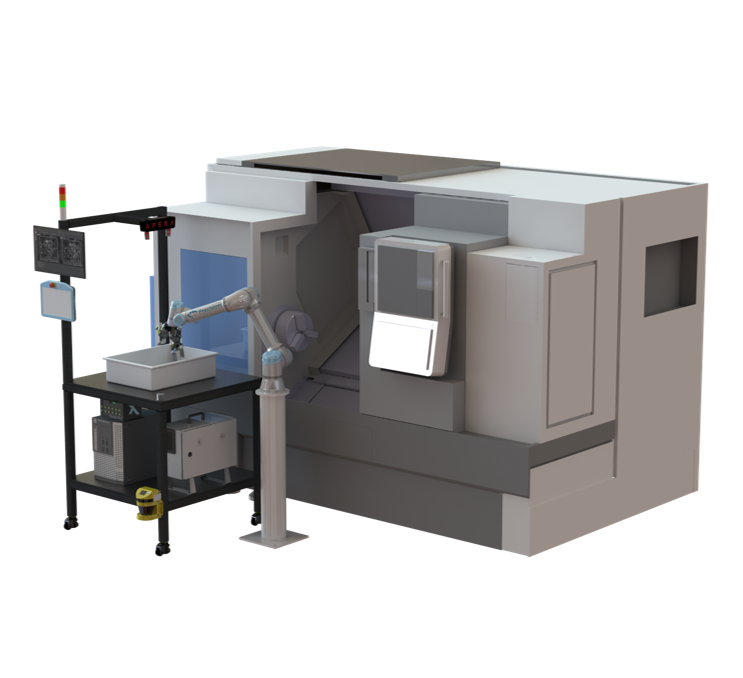

CNC Machine Tending

Utilizing Flexxbotics FlexCNC solution, combined with Apera bin picking, we can deliver an integrated machine tending solution across most CNC platforms. Imagine what you could do with additional shifts of lights out machine use or expanded utilization using the same staff that you have today.

-

Bin Picking

Bowl Feeding

Tray Systems -

Vision based inspection of critical features

Laser Marking

Our fully automated fiber laser marking system is powered by the industry leading MECCO laser marker supporting product marking up to 7” x 7” with cycle times as low as 7ppm. Integrated Apera 4D Bin Picking enables autonomous operation

-

Bin Picking

Bowl Feeding

Tray Systems -

Vision Verification for part marking

End of Line Packaging

Randomly oriented products can be identified and picked by the Apera vision system and placed in a customizable downstream process. These can be configured to include label applicators, case erectors, tape sealers and palletizing powered by Robotiq

-

Bin Picking

Conveyor Feed -

Vision verification for proper labeling and packaging

Inspection Gaging

Producing safety critical product components often requires 100% inspection. Gaging parts is a monotonous task that can also introduce repetitive motion injury risk to your employees. Our automated gaging solution eliminates human error, mitigates risk to your staff and enables maximum throughput.

-

Bin Picking

Bowl Feeding

Tray Systems -

InkCups Printer Tending

Supporting up to 8 bottles/min, this automation cell supports 2 Double Helix® Cylindrical Inkjet Printers from InkCups. Shown with a gravity feeder for 20 minutes of production, we can pair this with other part presentation approaches such as Apera for true lights out production.

-

Bin Picking

Gravity Feeder -

Packaging

Vision System Verification